NITROUS FLOWBENCH TESTING

Fast Lane Nitrous was the first company to flow test nitrous systems for the public (1996). Long before many other companies were around. We have flow tested & Jet mapped literally thousands of nitrous systems for racers and manufacturers. When you order the Flow Bench Testing service you will receive PPH of nitrous flow through every setting of your system. You can avoid another parts damaging cycle. It's the cheapest insurance you can buy! Every piece of your nitrous system gets my personal attention and is hand checked. Some parts are modified. Every nozzle is blueprinted, every solenoid is taken apart to check orifice dimensions, plunger configuration and lift rate. The system is blueprinted and then mapped-out with corrected nitrous-to-fuel ratio's on the Flow bench. This service includes our tuning tips pages that cover race fuel, fuel pressure regulators, setting fuel pressure, optimum bottle pressure, spark plugs, spark plug reading and Ignition timing information. I include more tuning information than any other nitrous tuner and do it at a more economical price. I believe that good information supplied to good racers, provides great results!

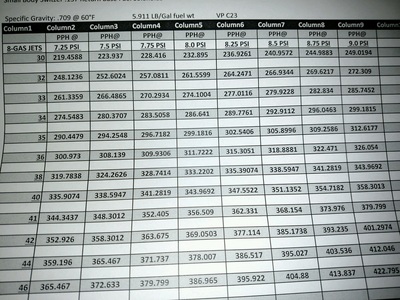

Plate Information: I go through all the parts. Blueprint and deburr the spray bars. Check the orifices, check the fittings for restrictions, go through all the lines, I blueprint the solenoids and open up the nitrous solenoid. I check plunger lift, as well as replace the plunger(s) if needed. I install new high flow fittings if needed. Once I have gone through and blueprinted all the parts and reassembled them, the system is then ultrasonically cleaned. Then its put on the Nitrous/Fuel Flowbench to flowmeter calibrate 4-6 HP levels of nitrous jets as well as flowmeter the fuel side to match with the proper N/F Ratio.

Direct Port Flow: On a Direct-port system I go through all the parts and check them, I do some modifications and rebuild some parts as needed. I blueprint the nozzles, lines, fittings and distribution blocks. I carbide ream the nitrous solenoids to equalize the orifices. The plunger lift is equalized and the plungers are replaced if needed, the fittings are modified for more flow or replaced with higher flowing fittings. Then it’s put on the Nitrous/Fuel Flowbench. I flowmeter the nitrous flow, check for vacuum on the fuel side and flowmeter the fuel flow to establish the proper Nitrous-to-fuel ratio range. Then flow both together to make sure the settings stay in the proper N/F ratio range. Calibrate 10-15 HP levels/Jet spreads-(Jets not included but can be purchased separately)

The systems will be better than new with corrected jetting and all my tech support as well. If you decide to send me your system(s) use the contact form below to get a “nitrous system spec sheet” and fill out as complete as possible, the shipping address is on the spec sheet and include it in the box with your system.

I will help you meet your performance goals. My goal is to provide you with the most powerful and reliable nitrous system available by providing a comprehensive approach to tuning your system. Call Robert (903) 590-0839 or email me at [email protected] if you are having trouble getting maximum performance and reliability from your system.

So if you’re looking for more horsepower, excellent tech help, and a competitive advantage contact me today!

Q16 Tune-ups available

C25 Tune-ups available

VP N02 Tune-ups available

C23 Tune-ups available

Dry System Mapping also available.

No E85

Plate Information: I go through all the parts. Blueprint and deburr the spray bars. Check the orifices, check the fittings for restrictions, go through all the lines, I blueprint the solenoids and open up the nitrous solenoid. I check plunger lift, as well as replace the plunger(s) if needed. I install new high flow fittings if needed. Once I have gone through and blueprinted all the parts and reassembled them, the system is then ultrasonically cleaned. Then its put on the Nitrous/Fuel Flowbench to flowmeter calibrate 4-6 HP levels of nitrous jets as well as flowmeter the fuel side to match with the proper N/F Ratio.

Direct Port Flow: On a Direct-port system I go through all the parts and check them, I do some modifications and rebuild some parts as needed. I blueprint the nozzles, lines, fittings and distribution blocks. I carbide ream the nitrous solenoids to equalize the orifices. The plunger lift is equalized and the plungers are replaced if needed, the fittings are modified for more flow or replaced with higher flowing fittings. Then it’s put on the Nitrous/Fuel Flowbench. I flowmeter the nitrous flow, check for vacuum on the fuel side and flowmeter the fuel flow to establish the proper Nitrous-to-fuel ratio range. Then flow both together to make sure the settings stay in the proper N/F ratio range. Calibrate 10-15 HP levels/Jet spreads-(Jets not included but can be purchased separately)

The systems will be better than new with corrected jetting and all my tech support as well. If you decide to send me your system(s) use the contact form below to get a “nitrous system spec sheet” and fill out as complete as possible, the shipping address is on the spec sheet and include it in the box with your system.

I will help you meet your performance goals. My goal is to provide you with the most powerful and reliable nitrous system available by providing a comprehensive approach to tuning your system. Call Robert (903) 590-0839 or email me at [email protected] if you are having trouble getting maximum performance and reliability from your system.

So if you’re looking for more horsepower, excellent tech help, and a competitive advantage contact me today!

Q16 Tune-ups available

C25 Tune-ups available

VP N02 Tune-ups available

C23 Tune-ups available

Dry System Mapping also available.

No E85

Flow Test/Blueprint & Jet Map- 2 Stage Direct Port Fogger

Flow Test/Blueprint & Jet Map- Dry Direct Port System

Flow Test/Blueprint & Jet Map- 2-Stage Dry Direct Port System

Flow Test/Blueprint & Jet Map- (2-Stage Direct-Port and Plate)

Flow Test/Blueprint & Jet Map- Conventional Plate System (Single Stage)

Flow Test/Blueprint & Jet Map- (2-Stage Plate, Multi Carb systems & Cross Bar)

Flow Test/Blueprint & Jet Map- (Three and Four Stage WET Direct Port)

Port customer supplied nitrous solenoid for more flow

Please download, fill out and print the following form with all your information and mail it with your parts. Please include any photos or other helpful information that you think will be needed. Any jobs that come in without this form will be set aside until this information is received. When sending a plate system to be flowed I will need your plate, lines, jets and solenoids. I can flow your Direct Port system without it installed on the manifold I have polycarbonate fixtures that I can flow your direct port system on if you prefer to send it without the manifold.